The role of the history of flow evolvement tends to be overlooked in traditional aircraft design. Therefore, under flow-separation circumstances, the flow around the airfoil is related not only to the current environment but also to the previous flow characteristics, and the history of flow evolvement should thus be considered in the design of low-Reynolds-number aircraft. Because of this, the trailing-edge stall is "soft" compared with the leading-edge stall and the lift is higher under the same conditions. For this type of stall, there is progressive and gradual movement of separation from the trailing edge toward the leading edge as the camber is increased. However, for other camber deformation paths, the stall is a type of trailing-edge stall. Therefore, the lift of the airfoil is rather low under the circumstances of large camber. During this stall process, flow separates rather suddenly and abruptly over the entire top surface of the airfoil, with the origin of this separation being at the leading edge. For some camber deformation paths, the stall is a type of leading-edge stall. Professor Yang's group found that the stall type determines the distinction. Research shows that on the occasion of flow separation, different camber deformation paths have totally distinct aerodynamic characteristics.

#AIRFOIL CAMBER SKIN#

The D-spar was made with acrylic materials and the skin of the aft section was made with polypropylene plastics.Īerodynamic load measurements and a flow visualization technique such as particle image velocimetry are combined to reveal the aerodynamic characteristics resulting from the camber deformation and corresponding flow structures, from which the complex mechanism is hopefully determined. As part of the lower surface is pulled into the D-spar, there is a discrepancy in the area between the upper surface and lower surface and the airfoil is thus asymmetric in other words, the airfoil has some camber. A servomotor was fixed in the D-spar to provide power to pull the lower surface of the aft section into the D-spar to a certain extent with the help of gearing. The substructure is designed to support a flexible skin that provides the aerodynamic shape and is capable of morphing. The substructure comprises five rows of hinge-like units ranked serially along the chordwise direction. This section aft of the spar is specially designed to have an internal substructure.

The D-spar does not undergo any deformation in the chordwise direction, and consequently, only the section aft of the D-spar can deform. A rigid D-spar, the primary load carrying member, extends from the leading edge of the airfoil to the 30-percent chord.

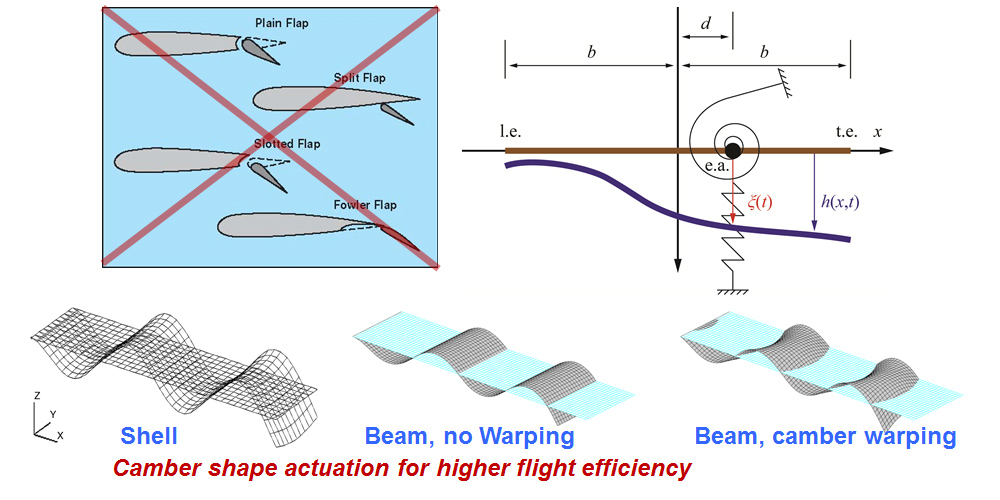

The baseline airfoil is assumed to have an NACA 0015 profile. The group firstly designed a type of variable camber airfoil test model whose camber can be changed smoothly. Their work, entitled "Experimental investigation on the quasi-steady flow separation behaviors of a variable camber wing", was published in SCIENTIA SINICA Physica, Mechanica & Astronomica, 2012, Vol. Through aerodynamic load measurements and related flow visualization, they distinguished the aerodynamic characteristics of the variable camber airfoil for steady and quasi-steady flow separation behaviors. Professor Yang Jiming and his group at the University of Science and Technology of China set out to explore this area of research. However, little attention has been paid to the quasi-steady aerodynamic characteristics resulting from the camber deformation and the effect of different initial flow conditions. Furthermore, compliant deformation of the airfoil helps explain the nature of the aerodynamic characteristics of a membrane wing such as that of a bat. Recent research has demonstrated that the variable camber airfoil has obvious advantages in terms of the control of separation and flight maneuverability. Better understanding and effective control of laminar separation is therefore valuable for improving the flight mechanics of low-Reynolds-number aircraft such as micro air vehicles (MAVs). In the case of low-speed aircraft, the performance of low-Reynolds-number airfoils is greatly determined by the relatively feeble separation resistance of the laminar boundary layer. In the field of aerodynamics, the use of a variable camber airfoil can improve aircraft flight performance and allow efficient multiple missions in biology, the concept of the variable camber airfoil can be employed to explain the mystery of animal flight. view moreĪircraft morphing, especially in the case of the variable camber airfoil, has potential from the viewpoints of both fundamental aerodynamics and flight application. Image: This image shows the construction of a variable camber airfoil and a real model.

0 kommentar(er)

0 kommentar(er)